Description

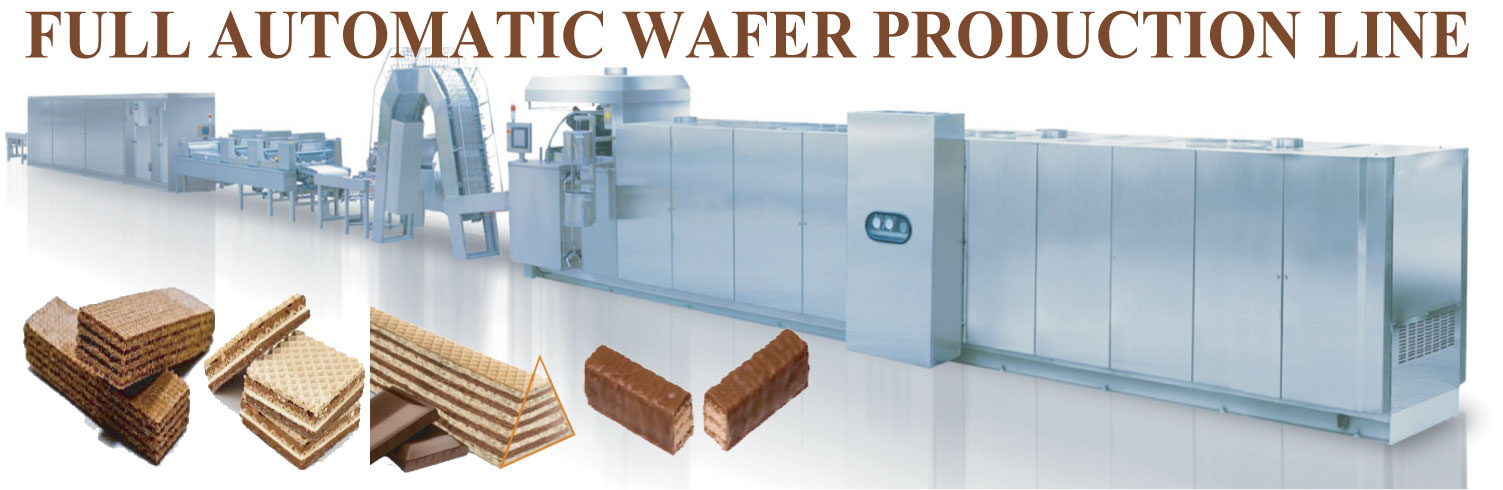

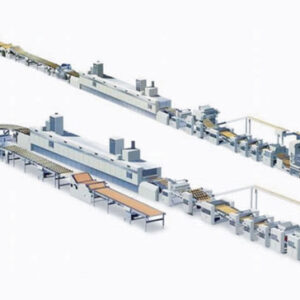

- Full Automation: The system automates the entire wafer production process, from mixing the dough to packaging the finished wafers.

- PLC Control: A Programmable Logic Controller (PLC) system allows for automated and easy control of the production process.

- Reputable Components: The system utilizes well-known brand components for key parts, such as SEW Germany for motors and SKF for bearings.

- Compact and Efficient Layout: The system is designed with a compact structure and rational layout, minimizing floor space requirements.

- High Yield and Reliability: Automatic operation ensures consistent production and a high yield of quality wafers.

- Easy Maintenance: The system is designed for easy maintenance and troubleshooting, minimizing downtime.

- Energy Efficiency: The system incorporates energy-saving designs, reducing overall energy consumption.

- Flexibility: The system can be adapted to produce various wafer shapes and sizes.

- Quality Control: The system includes features for even baking, consistent product quality, and a high finished product rate.

- User-Friendly Interface: The system typically features an HMI (Human-Machine Interface) operation panel for easy operation and monitoring.

- Continuous Operation: The system is designed for continuous 24-hour operation, with features like wear-resistant conveyor belts.